The first operation which is performed on the support of public lighting is the visual analysis.

From this analysis we establish all the geometrical parameters and detect all possible anomalies.

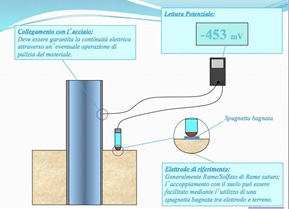

The corrosion potential is the first non-destructive test that is done after a visual inspection and provides information on the tendency to corrosion that the material possesses in its present state.

The value obtained, expressed in mV is the corrosion potential of the support in the interlocking zone, with respect to a reference electrode (normally Cu CuSO4) placed in direct contact with the surrounding soil.

The corrosion of public lighting poles depends on several factors: moisture, temperature, thermal excursion, pollutants, soil type, the presence of water, differential aeration. In order to evaluate this parameter making an electrochemical test "Non Destructive" using a special tool called Corrosimetro.

The corrosion rate is a test that results in the annual consumption of the support thickness and is measured in Micron / year, while providing the information to derive the value of the residual life support.

In order to check the status of the most vulnerable area of the support, we proceed with the unveiling of their underground portion and the demolition of the concrete component at the base, where present.

Completed the preparatory work leading to the base of support must be removed prior security and carried out a thorough cleaning of the entire area concerned.

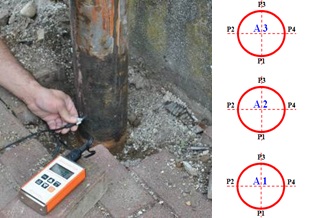

The thickness measurements measures are necessary to assess the state of degradation of the support in the joint area.

The detection points, are acquired in areas, where for experience and for case study, the principal problems of corrosion of the metal supports. The possibility of visual and tactile identification of areas most damaged by the operator may vary the acquisition points of standard thicknesses.

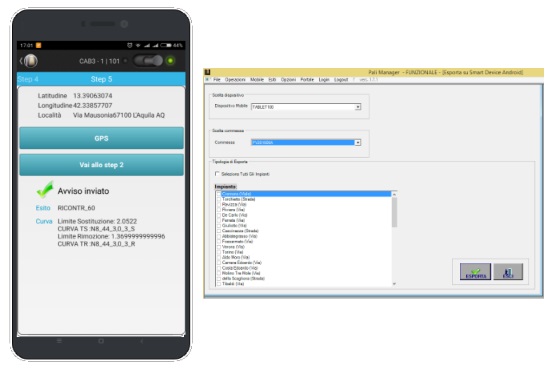

The software for the verification of Poles Manager consists of two applications: Smart Poles and Poles Manager Pali Smart is a software installed on the mobile device that allows operators to carry out the verification of the pile to be examined on site. The advantage of having a software on a mobile device is twofold: the operator is located in front of the pole and then the subject of verification can conduct an examination of the more accurate and more truthful pole having in real time the stability calculation on the basis of the geometric data, inserted. The integration of the software with the mobile device's camera allows to photograph the pole so as to ensure the authenticity of the verification.

DoubleShield is a new ANTI CORROSIVE concept Technology that is based on a double barrier of active and passive protection .

The product is formed from two different layers of material : a sacrificial anode for the inner part and a sealing membrane to the external part .

The result is a unique and exclusive product that provides active protection to the metal surface on which it is applied , and a physical - chemical passive protection against external agents .

DoubleShield is a product that has no solvents and is completely environmentally friendly . Designed to ensure a long life of the same , thus avoiding any future maintenance .

Upon completion of the above activities, integrating the results of those tests collected in the field of structural analysis through the use of a validated algorithm and the Tablet, the GECOMET system is able to provide all the information necessary to determine any critical issues and expectations of the support life. Such information is acquired and transmitted in real time, on a website platform that stores and makes available, possibly the client, accessing data, and the status of the checks. The final document produced certifies signed by a qualified engineer the status of pole inspected.