Concrete, by nature, is a non-uniform, non isotropic structural material consisting of aggregate particles, air voids and moisture distributed heterogeneously in an hardened matrix. Variations in its production and subsequent attack by the environment mean that concrete is not totally immune to defects although it is generally a durable and maintenance free material.

There is therefore a need for a regular system of inspection of all reinforced concrete structures so that any deterioration can be detected and recorded at its early stages, and a decision than taken on what remedial works, if any, should be carried out. However it must be noted that the periodic inspection to control and arrest deterioration or repair with apposite interventions, no way implies structural failure risk due to incorrect dimensioning or excessive overload on it. For all the above mentioned reasons a reinforced structure must be inspected taking into account all the possible causes of a failure event:

Reinfoced concrete deterioration is mainly due to corrosion of rebars for various reasons (clorides, carbonatation, moisture, external environment action etc.) that causes section loss for both reinforcement and concrete (spalling) and consequent structural resistance reduction. This aspect can be inspected with in situ tests and experimental activities in order to asses deterioration state and evolution rate.

Possible incorrect dimensioning must be considered analysing the whole structure and its components, creating a FEM model and verifying that structural safety margin is above the limits imposed by current normative.

Overloads or generally an incorrect use of the structure must be verified and compared with those the structure itself has been dimensioned for. This aspect can be verified with the comparison between model - normative and visual inspected loads.

Structure elements must be visual analysed and inspected with apposite test in order to asses the correct execution related to the final design (correct rebars quantity, geometry, concrete etc.).

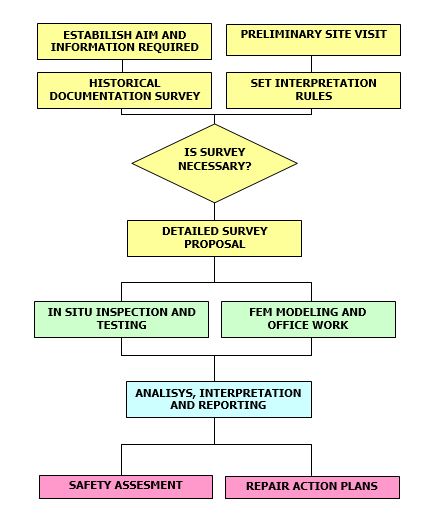

Careful planning is essential. Ideally a program must be evolved to obtain as much information as possible at the minimum cost and in the shortest time. Testing should as far as is necessary to get conclusions with a satisfactory degree of confidence and accuracy to meet the objective of the survey. The engineer responsible for the survey should obtain as much information as possible about the structure. The type of information which would be useful to collect during the documentation survey includes the following: - Date of construction; - Details of construction, including architectural, structural, geotechnical and “as built” drawings; - Present use of the structure; - Previous changes of use (if any); - Records of previous deteriorations and repairs; - Reports of previous surveys (if any). The importance of the documentation survey should not be under-estimated because it could indicate possible causes of failure risk or deterioration and assist therefore the proposals for a detailed investigation, sampling and testing. At this stage it may be necessary to make a site visit in order to asses a preliminary visual inspection useful for an optimal survey proposal. In the following a detailed list of possible test is reported.

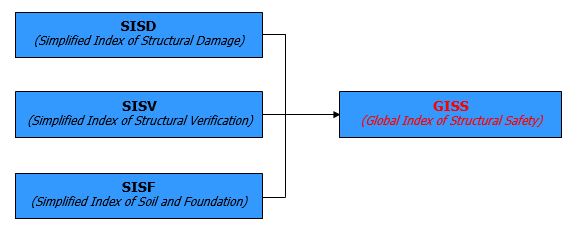

TESTING Architectural Survey Structural Survey Concrete mechanical resistance assessment with in situ and laboratory tests. Reinforcement mechanical resistance assessment with in situ and laboratory tests. Carbonatation Depth Clorides Depth and Concentration Crack Width Concrete electrical resistivity Reinforcement section loss Corrosion Rate Electrochemical Potential Mapping and related Statistical Analysis ANALYSIS AND INTERPRETATION Calculation of a standard index (SISD – Simplified Index of Structural Damage) about concrete deterioration for corrosion reasons taking into account also structural and geometrical features.

PRELIMINARY ELEBORATION FEM modelling of the structure TESTING Architectural Survey Structural Survey In situ dynamical analysis of the structure ANALYSIS AND INTERPRETATION Statical safety calculations and dynamical analysis FEM model updating with comparison between calculated and really in situ measured dynamical analysis. Calculation of a standard index (SISV – Simplified Index of Structural Verification) that takes into account incorrect dimensioning, incorrect execution, incorrect use etc.).

TESTING Geological site assesment 2D or 3D Electrical Resistance Tomography (ERT) Vertical mecanichal logs Penetrometer tests Laboratory tests on samples Architectural and structural Survey of foundation system ANALYSIS AND INTERPRETATION Geological and Geotechnical Report Calculation of a standard index (SISF – Simplified Index of Soil and Foundation) about foundation structural safety taking into account soils geotechnical feature and its possible effects on the structure.

The detailed testing proposal should take into account the current historical information about the structure. Every information loss must be substituted by appropriate in situ or laboratory tests. The output is the assesment of structural safety eventually constrained to focussed repair actions that will be described with accuracy and, if requested, planned. The estimation of deterioration rates is able to give informations about residual life of the structure time intervals for the next assesment survey. The whole modules and their relative index will be processed in order to obtain the final index (GISS – Global Index of Structural Safety)